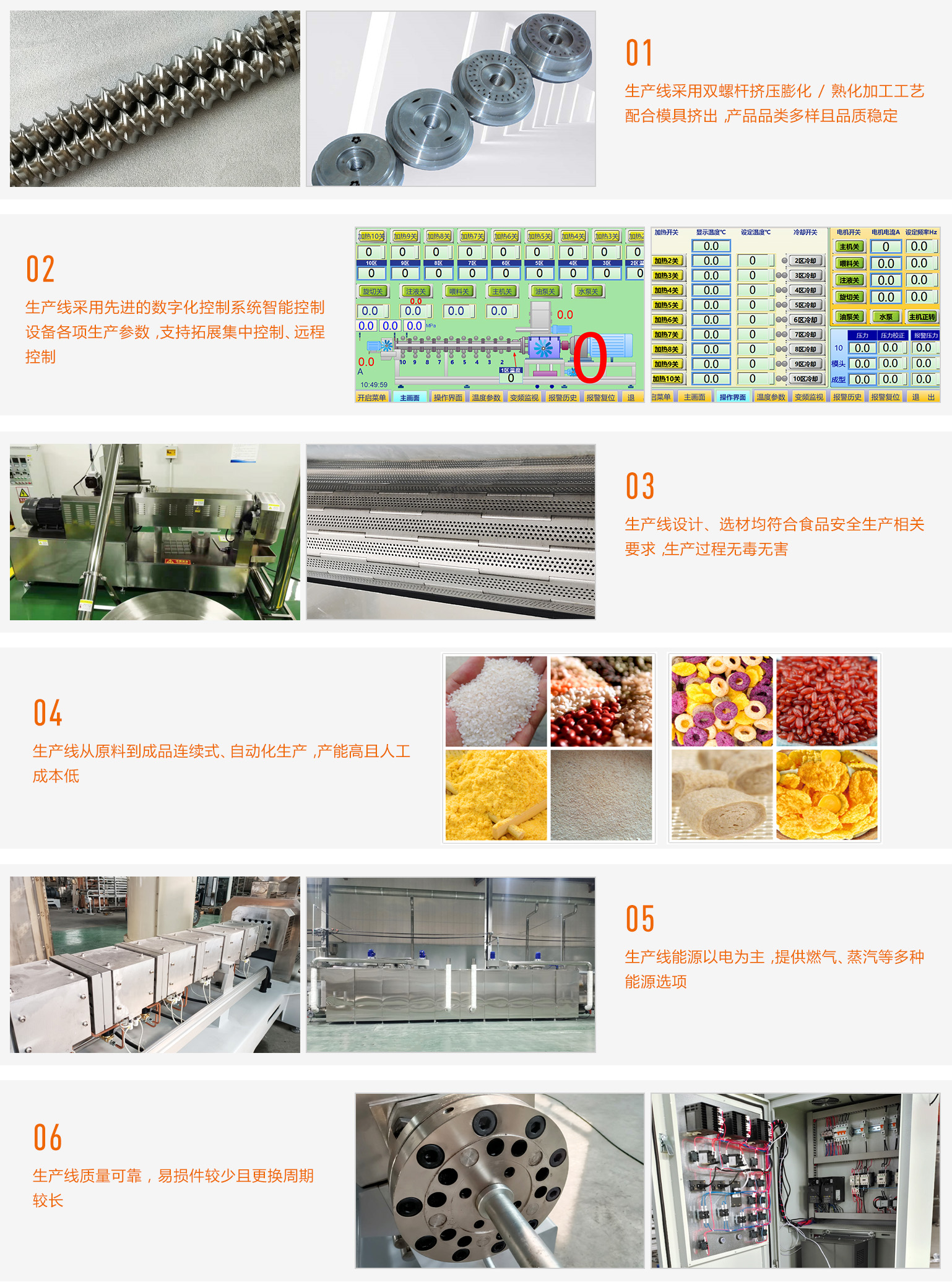

The production line of beverage pearl and crystal ball is an industrial automatic production line that uses twin-screw extrusion process to produce pearl powder balls and crystal balls in cold weather with starch, syrup, edible gum and other materials as raw materials. The production process of the production line includes batching, metering and injection, extrusion molding, cutting, cooling, etc; Its core technology lies in the extrusion process. The advanced multi-stage precise temperature control extrusion structure is adopted. After the liquid material is metered and injected into the twin-screw extrusion system, it changes its physical and chemical shape under the action of shearing and high temperature, and becomes easy to condense; Then it enters the cold extrusion section, with sufficient cooling effect and special die, so that the material can be continuously extruded from the die in solid state, and the product can be cut into spherical or block shape by the rotary cutting system while continuously extruding. This product is mainly used as an additive in milk tea, fruit tea and other drinks. Its trade names include non boiled pearl, cold weather crystal ball, crisp pope, etc; This kind of product has a texture of Q, and does not need to be boiled when eating. It can be refrigerated at low temperature and is not easy to corrupt. It can be used in store drinks or supermarket drinks. The beverage pearl and crystal ball extrusion production line is a highly automated industrial production line, which consumes less labor, runs continuously for no less than 72 hours, and there is no waste water or waste material discharged in the whole process; The food contact part of the equipment is produced and processed with food grade materials that meet the requirements of food safety production. The whole line is customized. The supporting scheme and workshop layout are customized according to the actual needs of the user. The designed output ranges from 100 kg per hour to thousands of kg, to fully meet your production needs.

生产线型号 | MG65饮品珍珠晶球生产线 | MG75饮品珍珠晶球生产线 | MG85饮品珍珠晶球生产线 | 定制化饮品珍珠晶球生产线 |

额定功率 | 90kw | 130kw | 160kw | 根据产能要求、产品要求提供定制化设计及生产服务 |

实耗功率 | 45kw | 65kw | 80kw | |

占地面积 | 80平方米 | 110平方米 | 130平方米 | |

设计产能 | 100-150kg/h | 200-300kg/h | 300-400kg/h | |

水消耗量 | ≤100kg/h | ≤200kg/h | ≤260kg/h | |

蒸汽消耗量 | 0 | 0 | 0 | |

燃气消耗量 | 0 | 0 | 0 | |

用工数量 | 2-3人 | 2-3人 | 2-3人 | |

主要材质 | 食品级不锈钢 | |||

生产流程 | 配料→计量注入→挤压→切断成型→冷却→成品 | |||

适用原料 | 淀粉、糖浆、可食用胶等 | |||

产品类别 | 饮品用珍珠粉圆、寒天晶球等 | |||

控制方式 | 控制柜调控生产参数,可扩展并支持远程集中控制 | |||

售后服务 | 上门指导安装并调试设备,提供基础生产技术指导;整线质保一年 | |||