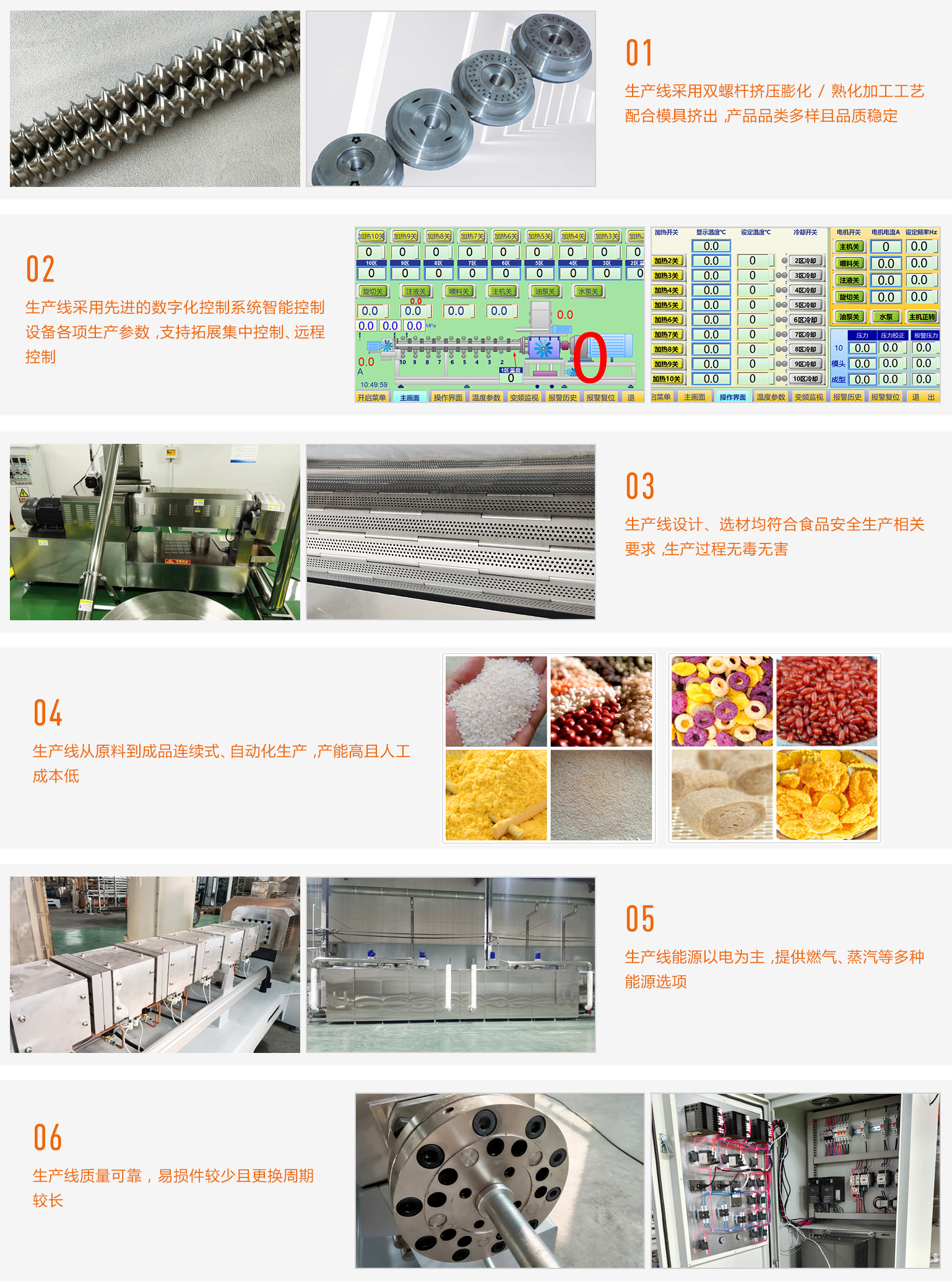

The puffed grain food production line uses various natural grains such as corn, rice, oats, and wheat as the main raw materials, and uses twin-screw extrusion technology to produce various granular, flake, or special-shaped grain puffed foods such as corn doughnuts, cereal bars, cereal balls, cereal chips, etc; This kind of product can be used as both snack food and functional meal substitute food. The main difference is that the main nutrients and taste are different due to different raw materials; Representative products include egg milk stars, wheat flavored chicken nuggets, cocoa chips, purple potato doughnuts, sandwich rice nuts, etc. After extrusion processing, this kind of product has strong aroma of grains, easy to absorb nutrition, and can be eaten directly or brewed. It tastes crisp and melts in the mouth; It can be used as complementary food for children and substitute food for adults. The production process of the production line is simple, and the whole process from raw materials to finished products is uninterrupted and continuous without manual operation. The continuous operation time is not less than 72 hours, and there is no waste water or waste material discharged in the whole process; Its main equipment includes mixer (mixing raw materials), twin-screw extruder (extruding, curing and granulating), dryer (removing water and improving taste), spray flavoring machine (spray flavoring), etc; All equipment in contact with food shall be produced and processed with food grade materials that meet the requirements of food safety production. The whole line shall be customized in design layout. The supporting scheme and workshop layout shall be customized according to the actual needs of customers. The design output varies from 100 kg to thousands of kg.

生产线型号 | MC65膨化谷物食品生产线 | MC70型膨化谷物食品生产线 | MC85型膨化谷物食品生产线 | 定制化膨化谷物食品生产线 |

额定功率 | 70kw | 130kw | 180kw | 根据产能要求、产品要求提供定制化设计及生产服务 |

实耗功率 | 35kw | 65kw | 90kw | |

占地面积 | 80平方米 | 120平方米 | 150平方米 | |

设计产能 | 100-150kg/h | 200-300kg/h | 300-500kg/h | |

水消耗量 | ≤30kg/h | ≤60kg/h | ≤100kg/h | |

蒸汽消耗量 | 0 | 0 | 0 | |

燃气消耗量 | 3m³/h(仅燃气加热型) | 5m³/h(仅燃气加热型) | 7m³/h(仅燃气加热型) | |

用工数量 | 2-3人 | 2-3人 | 2-3人 | |

主要材质 | 食品级不锈钢 | |||

生产流程 | 配料→混料→挤压膨化→烘烤→喷涂调味→成品 | |||

适用原料 | 大米、玉米、小麦、苦荞、燕麦、藜麦、部分豆类等 | |||

产品类别 | 膨化型休闲零食、谷物代餐辅食等 | |||

控制方式 | 控制柜调控生产参数,可扩展并支持远程集中控制 | |||

售后服务 | 上门指导安装并调试设备,提供基础生产技术指导;整线质保一年 | |||