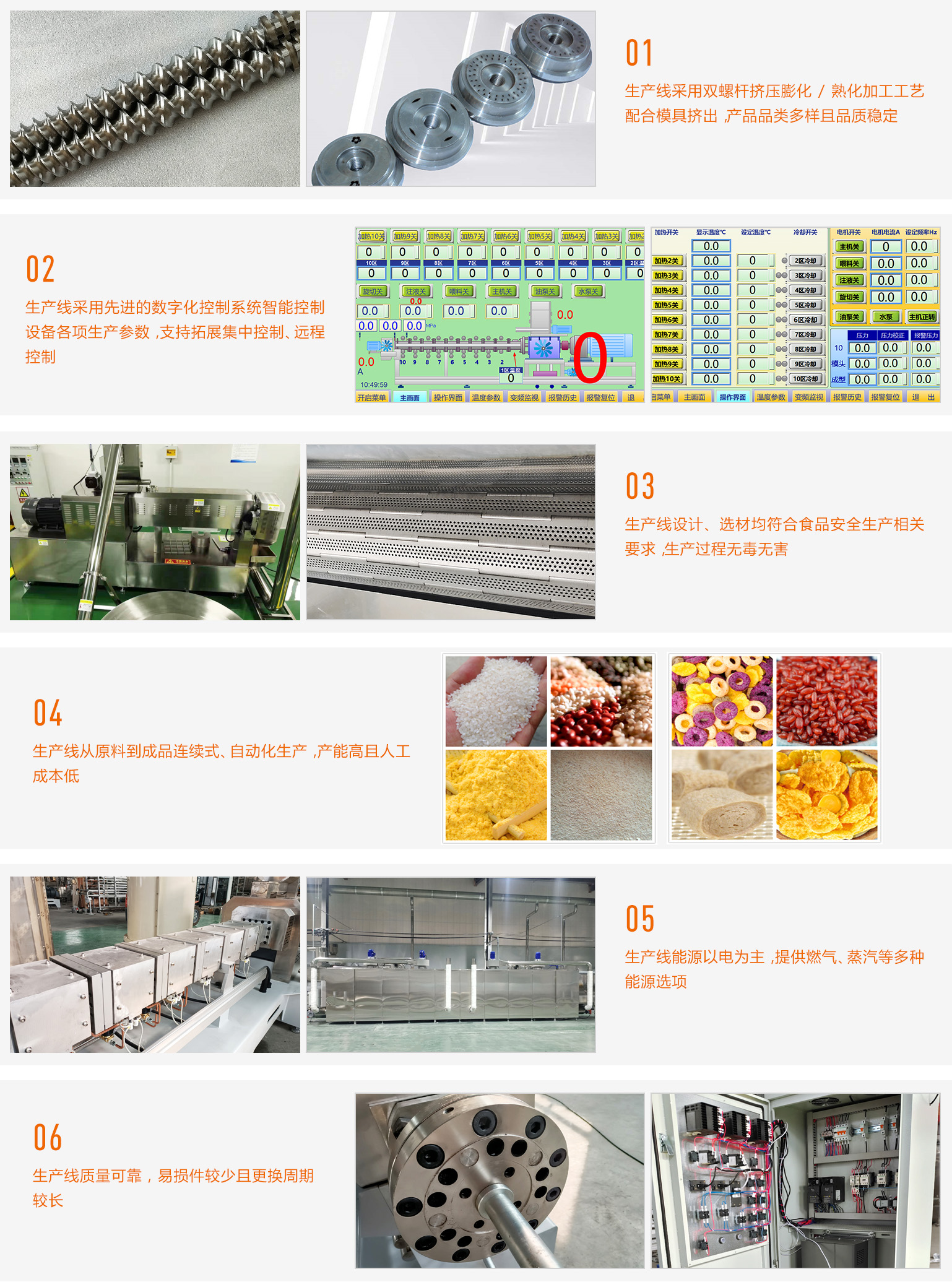

The fried puffed food production line uses rice flour, starch, wheat flour and other cereal flour as the main raw materials for production, and uses twin-screw extrusion and frying technology to process the raw materials into various leisure puffed foods, such as the commonly seen crispy fried rice crisps, salad bars, shell crisps, small fried dough twist, potato chips, potato chips and various 3D shaped products on the market; According to the process details, the above products can be classified into once puffed fried food and twice puffed fried food; The former does not need to be dried and fried directly after extrusion, and the product tastes crispy and hard, so the equipment scale is relatively small; The latter needs to add a low-temperature drying process after being made into billets by extrusion molding process. When the product moisture volatilizes completely, it will enter the frying link. During the frying process, the product will be expanded twice, with better expansion and crisp taste, but the equipment scale is relatively large. The production process of our company's fried puffed food production line is simple, and the whole process from raw materials to finished products is uninterrupted and continuous. The continuous operation time is not less than 72 hours, and there is no waste water or waste material discharged in the whole process; Its main equipment includes mixer (mixing raw materials), twin-screw extruder (extrusion and extrusion molding), shaping and cutting machine (auxiliary molding and cutting), dryer (moisture removal), fryer (frying to improve taste), spray flavoring machine (spray flavoring), etc; All equipment in contact with food shall be produced and processed with food grade materials that meet the requirements of food safety production. The whole line shall be customized in design layout. The supporting scheme and workshop layout shall be customized according to the actual needs of customers. The design output ranges from 100 kg to hundreds kg.

生产线型号 | MC65油炸膨化食品生产线 | MC70型油炸膨化食品生产线 | MG75型二次膨化类油炸膨化食品生产线 | 定制化油炸膨化食品生产线 |

额定功率 | 100kw | 120kw | 260kw | 根据产能要求、产品要求提供定制化设计及生产服务 |

实耗功率 | 50kw | 60kw | 130kw | |

占地面积 | 60平方米 | 70平方米 | 150平方米 | |

设计产能 | 100-150kg/h | 150-200kg/h | 200-300kg/h | |

水消耗量 | ≤30kg/h | ≤60kg/h | ≤100kg/h | |

蒸汽消耗量 | 0 | 0 | 0 | |

燃气消耗量 | 5m³/h(仅燃气加热型) | 6m³/h(仅燃气加热型) | 18m³/h(仅燃气加热型) | |

用工数量 | 2-3人 | 2-3人 | 4-5人 | |

主要材质 | 食品级不锈钢 | |||

生产流程 | 配料→混料→挤压膨化→干燥→油炸→喷涂调味→成品 | |||

适用原料 | 米粉、面粉、淀粉等 | |||

产品类别 | 油炸型膨化食品;锅巴片、妙脆角、沙拉条、贝壳酥、小麻花、薯条、薯片及各种3D异形产品 | |||

控制方式 | 控制柜调控生产参数,可扩展并支持远程集中控制 | |||

售后服务 | 上门指导安装并调试设备,提供基础生产技术指导;整线质保一年 | |||